Essential Factors To Consider for Choosing the most effective Engine for Your Demands

In the realm of selecting the optimal engine to satisfy your demands, a number of essential aspects demand careful consideration to make sure ideal efficiency and effectiveness. From the nuanced equilibrium in between power and efficiency to the often-overlooked facets of upkeep and solution demands, each element plays a critical role in figuring out the most suitable engine for your certain demands.

Power and Performance

When examining engines for optimal efficiency, it is important to prioritize both power result and performance. Effectiveness refers to how well the engine converts fuel right into functional energy. By thoroughly evaluating both power and efficiency, you can choose an engine that provides optimal efficiency and fulfills your demands effectively.

Gas Efficiency and Economic Climate

Gas effectiveness refers to the engine's capacity to convert gas into power with marginal waste, straight impacting operating prices and ecological sustainability. Engines with greater gas efficiency not only reduce gas expenditures but also lower carbon emissions, adding to a greener operation.

Compatibility and Application

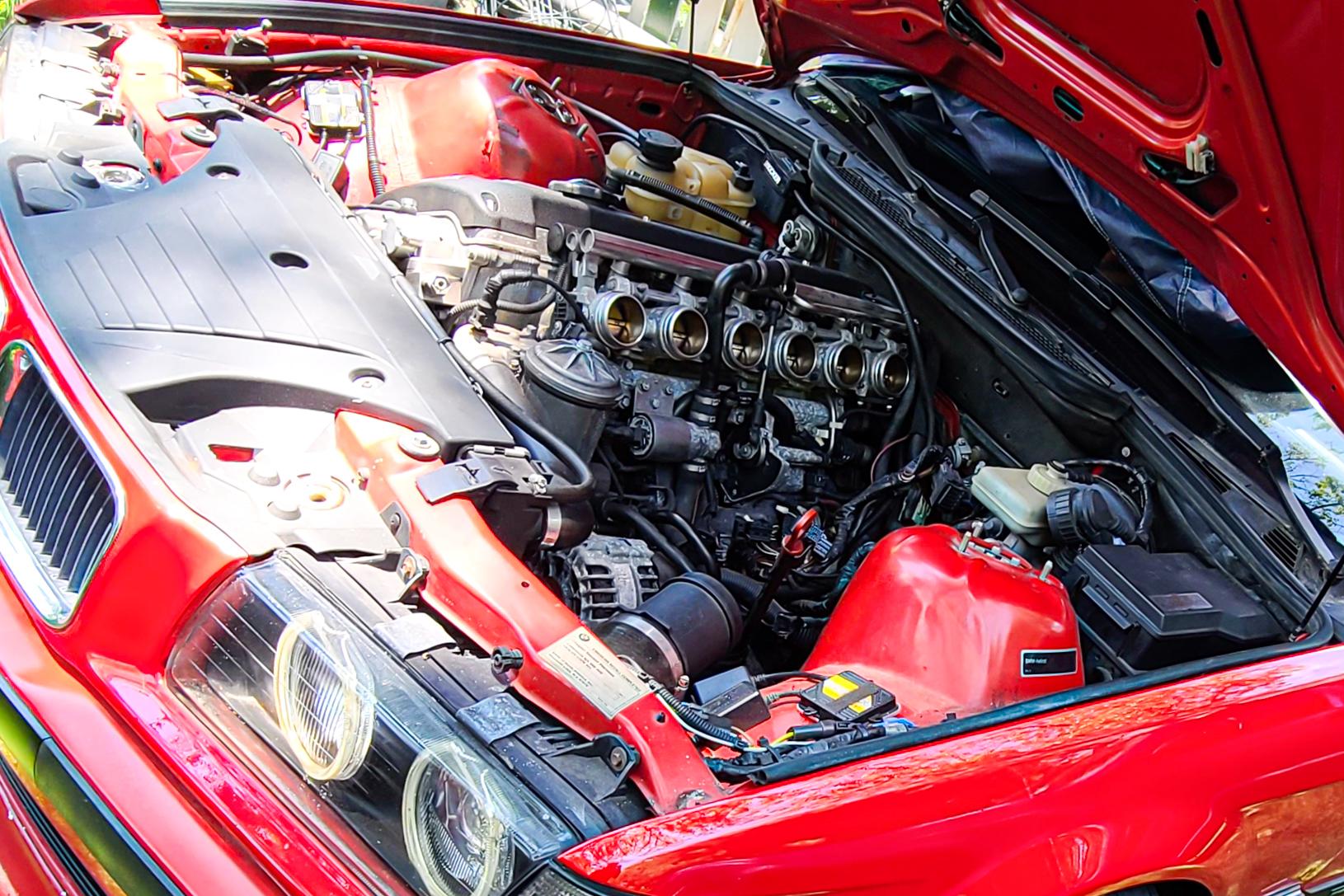

Taking into consideration the gas effectiveness and economic climate of an engine, the next important aspect to address is its compatibility and application within specific functional contexts. Compatibility describes just how well the engine integrates with the overall system or devices it powers. It entails factors such as physical measurements, mounting options, electric user interfaces, and control systems. Making certain compatibility is important to stop issues such as getting too hot, resonances, or power discrepancies (bmw 318ti).

In addition, the application of the engine is just as vital. Different engines are developed for details purposes, whether it be industrial machinery, marine vessels, automobiles, or power generators. Comprehending the intended application enables the choice of an engine that can deliver the required power result, torque, and functional characteristics. A high-revving engine designed for performance cars and trucks would not be ideal for durable building tools that requires high torque at reduced speeds.

Maintenance and Service Requirements

Upkeep and service needs play an important role in ensuring the durability and optimal performance of an engine. Normal upkeep is necessary to prevent failures, expand the life expectancy of the engine, and keep its performance. When picking an engine, it is essential to take into consideration the producer's suggested maintenance timetable and the availability of service facilities or certified service technicians.

Aspects such as the regularity of oil changes, filter substitutes, and general evaluations can substantially influence the engine's performance. Some engines might require more frequent maintenance based upon their style and use, while others might have longer discover this periods in between upkeep checks. It is important to follow these service requirements to prevent expensive repair work and unexpected downtime.

Cost and Budget Considerations

When selecting an engine for a certain application,Budget plan restraints typically play a considerable function in the decision-making process. When considering the expense and budget implications of choosing an engine, it is vital to evaluate not only the preliminary purchase price yet likewise the lasting expenditures connected with maintenance, gas intake, and potential upgrades or fixings. It is critical to strike a balance in between the upfront price of the engine and its total lifecycle expenses to make certain that the chosen engine continues to be monetarily sustainable throughout its operational life-span.

Variables such as gas sturdiness, reliability, and performance can directly impact the overall cost of possession of an engine. While an extra expensive engine may have greater ahead of time expenses, it find here could potentially result in reduced upkeep and gas expenses in time, therefore offering much better value in the future. Additionally, thinking about the availability and cost of spare parts, as well as the simplicity of upkeep and service, can assist prevent unforeseen economic stress in the future. Clicking Here By thoroughly assessing these price and spending plan considerations, you can make an informed choice that aligns with your operational requirements and monetary restraints.

Verdict

Fuel efficiency refers to the engine's capability to transform gas into power with very little waste, directly affecting operating costs and environmental sustainability.Variables affecting gas effectiveness include engine style, combustion effectiveness, and overall performance optimization. Additionally, choosing the appropriate gas type and quality as advised by the engine producer can even more improve efficiency and extend engine life-span.

Engines with excellent use functions and readily available parts can reduce upkeep expenses and decrease the time the engine is out of operation - bmw 318ti. It is crucial to strike a balance between the ahead of time expense of the engine and its total lifecycle expenses to make certain that the chosen engine stays economically sustainable throughout its functional life expectancy